The demand for electronic components is increasing year by year, and global companies are gradually cooperating with different business models. From the beginning, OEM( Original Equipment Manufacturer ), ODM (Original Design Manufacturer), and JDM(Joint Design Manufacturer) are all manufacturing models that often appear in electronic manufacturing services.

Grand-tek technology has own production line, provides SMT process services, and testing equipment, complete and quality manufacturing standards, to solve time and cost problems for customers.

SMT Assembly Process

What does surface mount mean?

Surface-mount technology is a technology for mounting electronic components on the PCB. It prints solder paste on the PCB, installs various SMD parts, and then reflows with hot air to combine the electronic parts with the PCB. A process that can be fully automated.

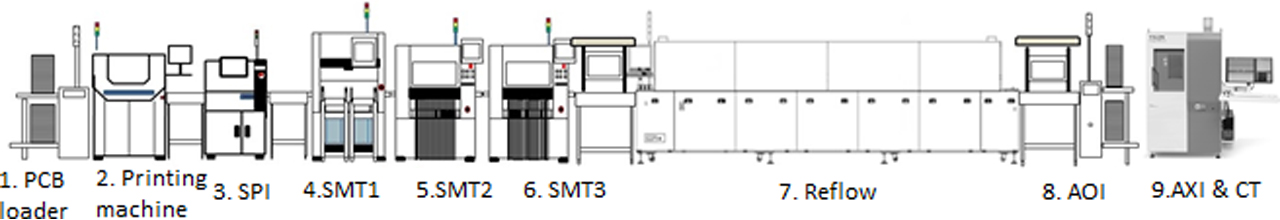

Process of SMT manufacturing

Step 1. PCB loader: Automatically placed PCB into the rack of solder printing machine.

Step 2. Printing Machine: Used to print the solder paste to bare printed circuit board.

Step 3. SPI: After solder paste printing, used for checking the thickness, area, and volume distribution of solder paste printed on the PCB

Step 4-6. SMT 1, 2, 3…: The surface mount components(SMC) will accurately place on the PCB pads by moving the placement head of SMT machine.

Step 7. Reflow: The reflow soldering is a process after SMT process in the SMT lines, which is responsible for melting the solder bonded between circuit boards and components, then cold down to form the reliable electric connection.

Step 8. AOI: In SMT production lines, AOI(Automated Optical Inspection) machines are used before and after reflow soldering. It is able to detect the placement failure of components before soldering in pre-solder inspection also the soldering failure in post-solder inspection.

Step 9. AXI&CT: Automated X-ray inspection (AXI) uses X-rays as its source, instead of visible light, to automatically inspect features, which are typically hidden from view. And CT(Circuit Testing) also is a method of testing which helps detect defective components by using an electrical probe to check components at individual points.

What are the advantages of surface mount technology?

- Less internal connecter.

- Easier on-line assembly, more efficient and less failures.

- More robust, more reliable.

Our capability

Our equipment

SMT Industrial Manufacturing

Smart Sensor PCBA

Sensor cable application require PCBA integration within the plastic mechanical housing or mounting process to ensure IP67 grade for outdoor usage.

Outdoor Power & Surge protector

Power & Surge for outdoor application is necessary. Worldwide approval standard & certification for outdoor weatherproof and wide temperature range compliance can be achieved.

Thermal dissipation Layout placement

Good layout placement prevent heat accumulation within the PCBA.

Telecommunication FMC modules

Integrated design with RF FMC board with build-in thermal solution, such as heat sink, thermal pad, glue, ect.